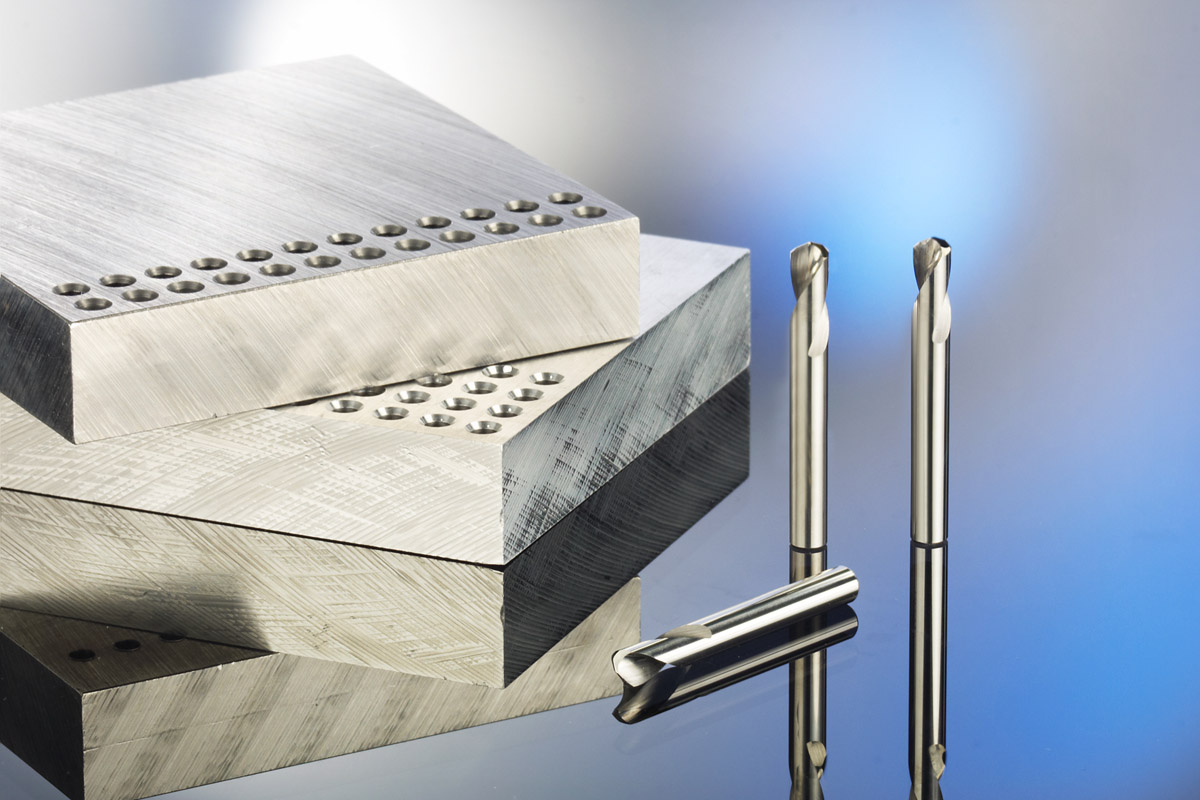

Although we are looking at other technologies perhaps laser drilling as an option, we and our clients do still favour conventional micro-drilling methods. Our experience has taught us that the end result is a cleaner and rounder finish. The advanced drilling technology employed by SMALL HOLE DRILLING Ltd. is particularly useful where due to the nature of the material being worked, lasers or the use of EDM drilling has the potential to damage or undermine the material being worked on.

Microdrilling

After microdrilling we carry out quality control of both the the holes themselves and the location of the holes. The quality and outcome of all the other engineering operations and the entire production is dependant on the quality of the inner surface of the holes and the edges of the holes.

Checking drilled holes

Checking the correct diamteres and the locations of the holes involves us in making measurements with a precision of tenths of micrometers. Using an optical projection device the image of enlarged holes can be projected onto the focussing screen to ensure correct dimensions. Measuring distances between holes and checking their correct locations is accurately undertaken using the latest image processing techniques using an optical system on custom or line image sensor.